- Home

- ESG Management

- Social

- Quality Management

ESG Management

Social

SK ecoengineering seeks quality management based on the international standard ISO 9001 to deliver the best quality that meets the needs of internal and external customers. To do so, we carry out project inspections and support activities during the design and construction phases for technical service by expert organizations and proactive quality risk management. We also focus on improving work productivity by adopting DT for quality management, thereby securing core competitiveness and creating successful project deliverables on the basis of New EPC.

As a company providing differentiated solution based on Customer CQSS Value-up,

SK ecoengineering recognizes quality as a core value.

Its quality policy aims to secure the happiness of stakeholders and society through customer satisfaction.

- We provide optimal products and services through on-site quality management.

- Based on our basic standards and principles, we practice compliance management by establishing a quality management system.

- We prevent accidents by eliminating their root causes through systematic, data-based quality risk management.

- We pursue shared growth through quality cooperation with business partners.

- We contribute to the continuous growth and development of the company through innovation and advancing the quality management system.

Our quality management roadmap is to build a comprehensive system to support our leap forward as a Net Zero Tech Solution company with global top-tier competitiveness. As part of the roadmap, we form a team of experts for each construction type who are capable of advising customers on technical solutions to assess risks and suggest remedies, while delivering technical solutions to internal and external customers to improve productivity and prevent rework. We will also continue to improve our quality management system to prevent quality accidents and minimize risks at all stages of a project through data-based risk detection using the DT system.

| Category | Goals | ||

|---|---|---|---|

| 2023 | 2024 | 2025 | |

| Resources and capabilities | Build an expert organization and conduct quality activities based on technical know-how | Expand the expert organization for each part of EPC | Leverage senior experts to represent the Lead / Help / Check organizations to provide preliminary risk diagnosis and solutions from project contract stage to closure |

| Systems and processes | Operate Smart Construction Platform(S.CON) for all ongoing projects | Lay the foundation for data packing / LL(Lessons Learned) in the S.CON | Build a preliminary risk hedging process based on data analysis |

SK ecoengineering engages in various quality accident prevention activities. For instance, we provide initial quality support to set up the quality system and assess risks at the initial phase of a project. and carry out regular and ad-hoc quality audits considering each project's characteristics and processes. Regular audits are conducted using our expert organizations to ensure high quality in design and construction, and ad-hoc audits are conducted when we deem additional audits necessary or when quality issues arise. We ensure issues raised in an audit are addressed 100% by each site, while strengthening the efficiency of quality work based on experience and data to prevent recurrence.

| Category | 2022 | 2023 | 2024 (as of July) |

|---|---|---|---|

| Criminal Penalties (Cases) | 0 | 0 | 0 |

| Administrative Actions (Cases) | 0 | 0 | 0 |

To implement quality management and prevent material accidents, SK Ecoengineering has established a four-stage Quality Gate system to verify the capabilities of our Biz. Partners and ensure construction quality. Through evaluations at the registration, bidding, and contract stages, we proactively manage quality. Additionally, quarterly performance assessments are conducted, where outstanding Biz. Partners receive incentives while lower-performing partners receive warnings to reinforce accountability and motivation. This approach ensures continuous improvement in quality management and alignment with customer requirements.

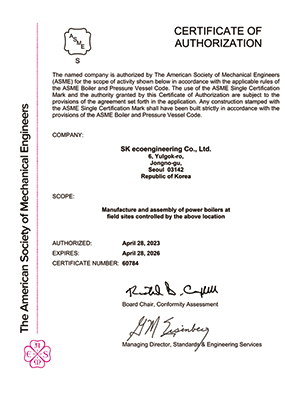

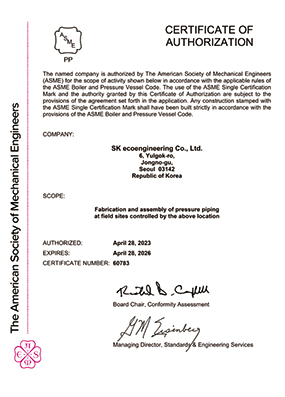

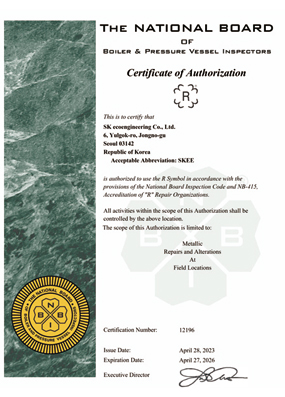

SK ecoengineering has obtained and maintains quality certifications from accredited certification organizations in an effort to enhance customer trust in the global market. We have acquired ISO 9001, the international standard for quality management systems, and have acquired ASME(American Society of Mechanical Engineers) quality certification as a preliminary step to be accredited for our quality management procedures for boilers and pressure vessels, which are key technologies in the plant industry.

ISO 9001

ISO 9001

ASME S

ASME S

ASME PP

ASME PP

ASME R

ASME R

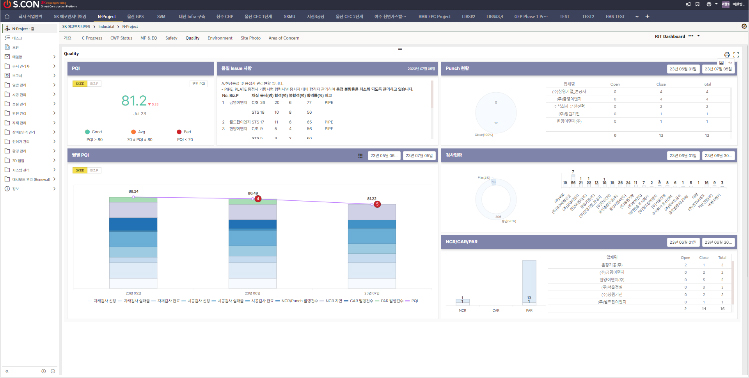

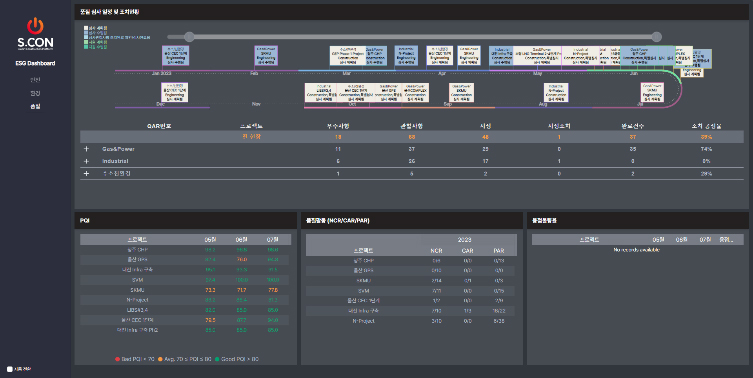

SK Ecoengineering has developed S.CON (Smart Construction Platform), a DT (Digital Transformation) system for monitoring and managing quality activities across all projects to ensure transparent quality management. This system aggregates real-time quality data, including inspection statuses, non-conformance reports, and key issues, providing quantitative indicators of quality performance. The Project Quality Index (PQI) is visualized on a dashboard, enabling objective quality assessments. Additionally, an ESG dashboard is separately managed to enhance the visibility of our quality initiatives. SK ecoengineering has obtained and maintains quality certifications from accredited certification organizations in an effort to enhance customer trust in the global market. We have acquired ISO 9001, the international standard for quality management systems, and have acquired ASME(American Society of Mechanical Engineers) quality certification as a preliminary step to be accredited for our quality management procedures for boilers and pressure vessels, which are key technologies in the plant industry.

S.CON Project Dashboard

S.CON Project Dashboard

S.CON ESG Dashboard

S.CON ESG Dashboard

At SK ecoengineering, we operate a quality training system to cultivate a quality mindset among all employees. Through mySUNI, SK Group's training platform, all employees can access courses on quality management, quality activities, quality management systems, and quality accident cases. For projects, each project team sets up an annual training plan and new joiner training plan, and conducts training for all stakeholders at the site, including employees and business partners, on quality work procedures and system operation.

mySUNI quality training

mySUNI quality training

On-site quality case training

On-site quality case training